Construction of the extraction shop for the oil extraction plant JSC Orelmaslo

The plant of vegetable oils of JSC Orelmaslo is the largest producer and exporter of the region. The company's products are sold not only in Russia, but also in the European Union, the Middle East and China.

On February 25, 2019, the opening ceremony of the construction of a new extraction shop was held at the Orelmaslo plant. In addition to sunflower and rapeseed, the plant will be able to process soy and produce soy meal — a product that is widely in demand in the production of animal feed.

The company Reztoff acted as the General Contractor for the implementation of this project. The contract was a continuation of cooperation with JSC Orelmaslo: previously, work was carried out on the manufacture and installation of metal structures for the oil cake storage warehouse (132 tons).

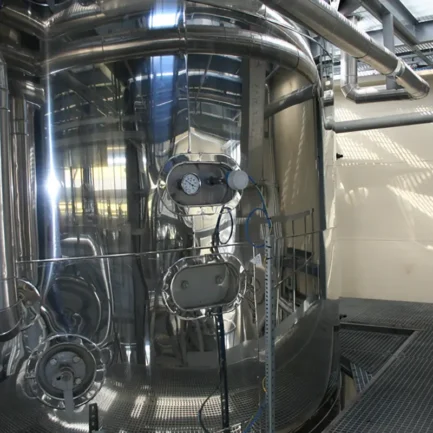

We started building the extraction shop in March 2019 and it was fully built in April 2020. The equipment supplier was the British company Europa Crown Limited.

In August 2020, the new workshop of the Orelmaslo creamery underwent commissioning, and in October it was launched. The capacity of the creamery taking into account the new shop will be 400 thousand tons per year.

| Industry sector: | Food Industry |

|---|---|

| Project: | Construction of the extraction shop for the oil extraction plant JSC Orelmaslo with a capacity of 1200 tons processing of sunflower seeds per day |

| Site location: | 21, Maslozavodskoy per., Orel |

| Terms of the work completion on site: | March 2019 – April 2020 |

| The description of the performed works: |

General contract for the construction of the extraction shop:

The facility included the following structures:

|

Production and installation

of metal structures

- 400 tons of assembled structures;

- The work completion period is 7 months.

Installation of sandwich-panels

- 1,990 m² of sandwich-panels;

The work completion period is 3 months. - 1,033 m² of ventilated facade;

The work completion period is 4 months.

Installation of equipment

and process pipelines

- 323.88 tons of technological equipment of the extraction shop;

- 165.5 m of conveyors and bucket elevators;

- 4.5 km of industrial pipelines;

- The work completion period is 5 months.

Isolation works

- 1,885 m² of equipment and pipeline insulation;

- The work completion period is 4 months.

Еlectrical works. Installation of control

and measuring devices and automation

- 55,240 m of cables;

- 9,119 m of trays and cable traks;

- 9,479 m of external power supply networks;

- 405 devices of automatic equipment.

Commissioning

In August 2020, the new workshop of the Orelmaslo creamery underwent commissioning.

The work on putting the new workshop into operation was carried out by our specialists with the specialists of the British company Europa Crown Limited — the main supplier of equipment. As a result of the tests, the plant was brought to its planned capacity.

The opening of the new production facility will allow the creamery to produce high-quality products that meet the requirements of Russian and international standards. An eco-friendly extraction shop will make the plant multifunctional for processing oilseeds.

The grand opening of the workshop took place on October 6, 2020. The processing capacity of the constructed facility will be 1,2 thousand tons of seed oil per day.