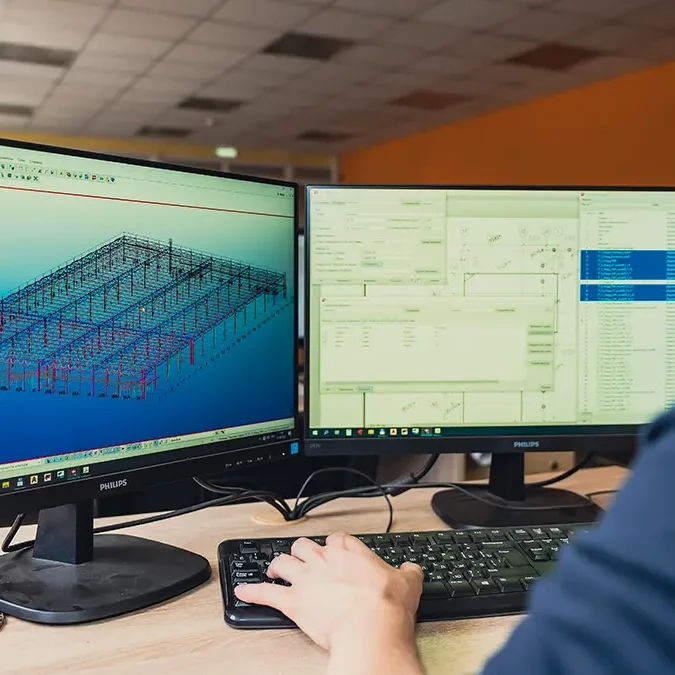

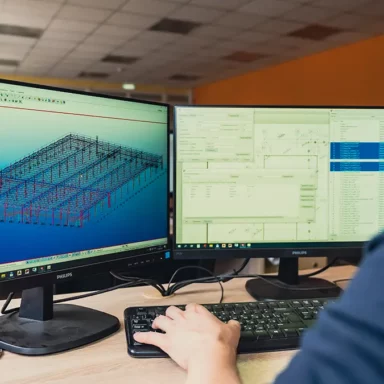

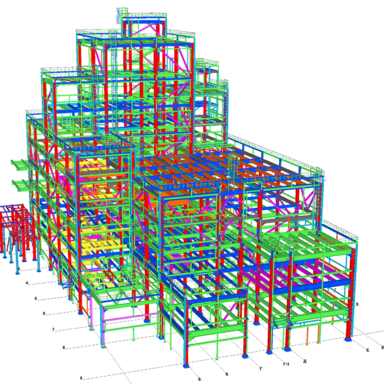

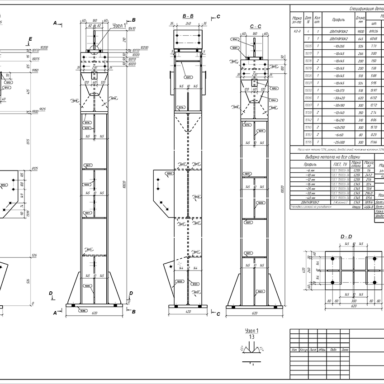

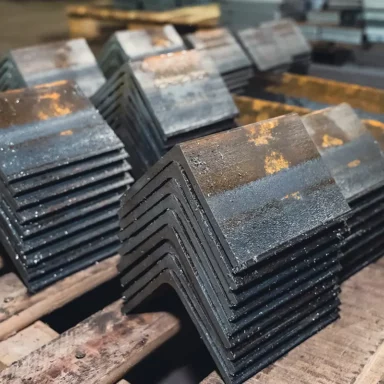

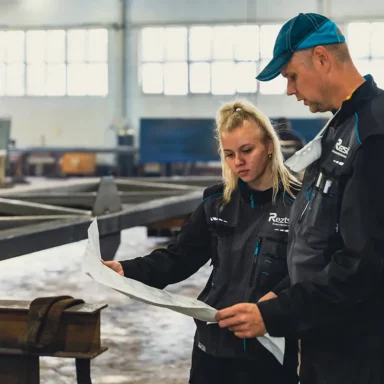

The metal fabrication includes the following stages: design, production planning, fabrication, quality control, delivery to the facility. More than 50 employees are involved in the process.

Metal fabrication is performed:

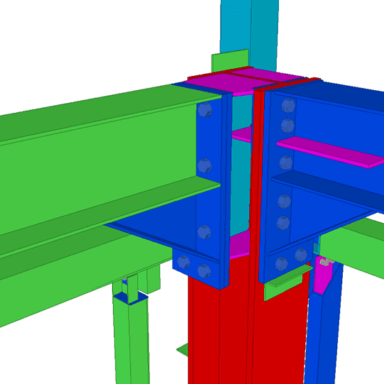

- according to the structural engineering drawings of Reztsoff own design department or the customer’s one;

- in compliance with the requirements of the terms of reference, applicable norms, regulations, State All-Union standard (GOST), construction norms and regulations (SNiP);

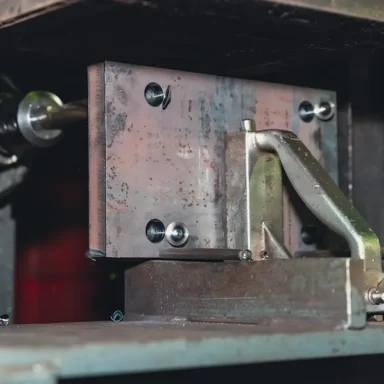

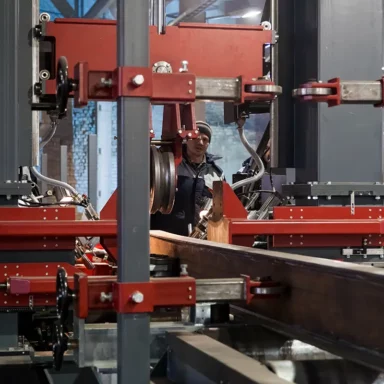

- on automated machines and CNC-controlled lines;

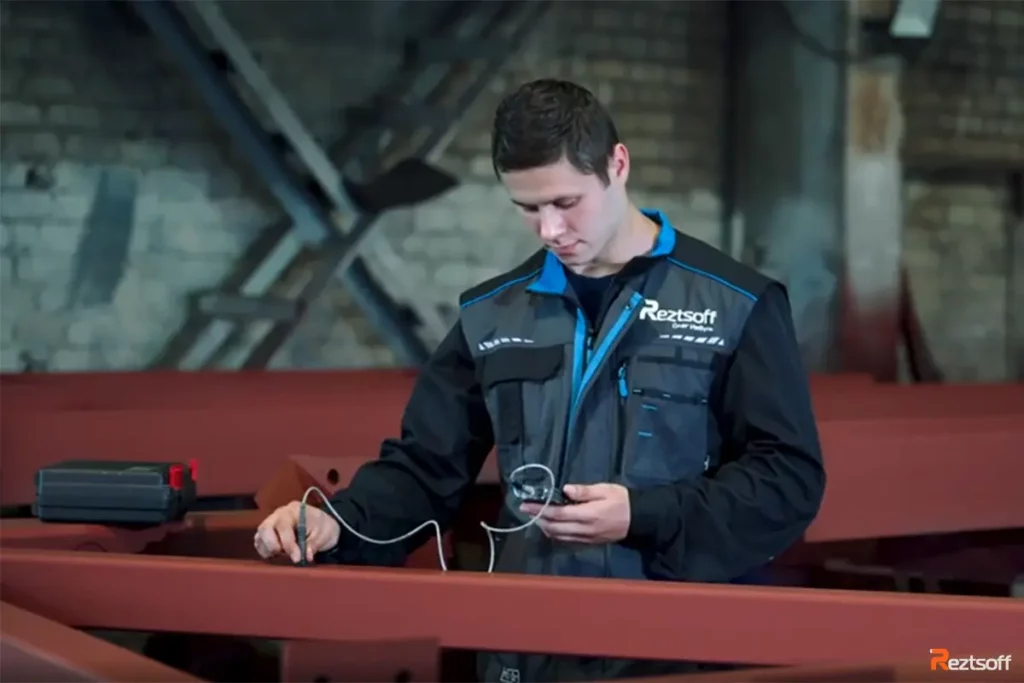

- with nondestructive methods for incoming and in-process inspection along with acceptance testing.

Based on our experience, the quality and price of metal structures depend on the following factors.