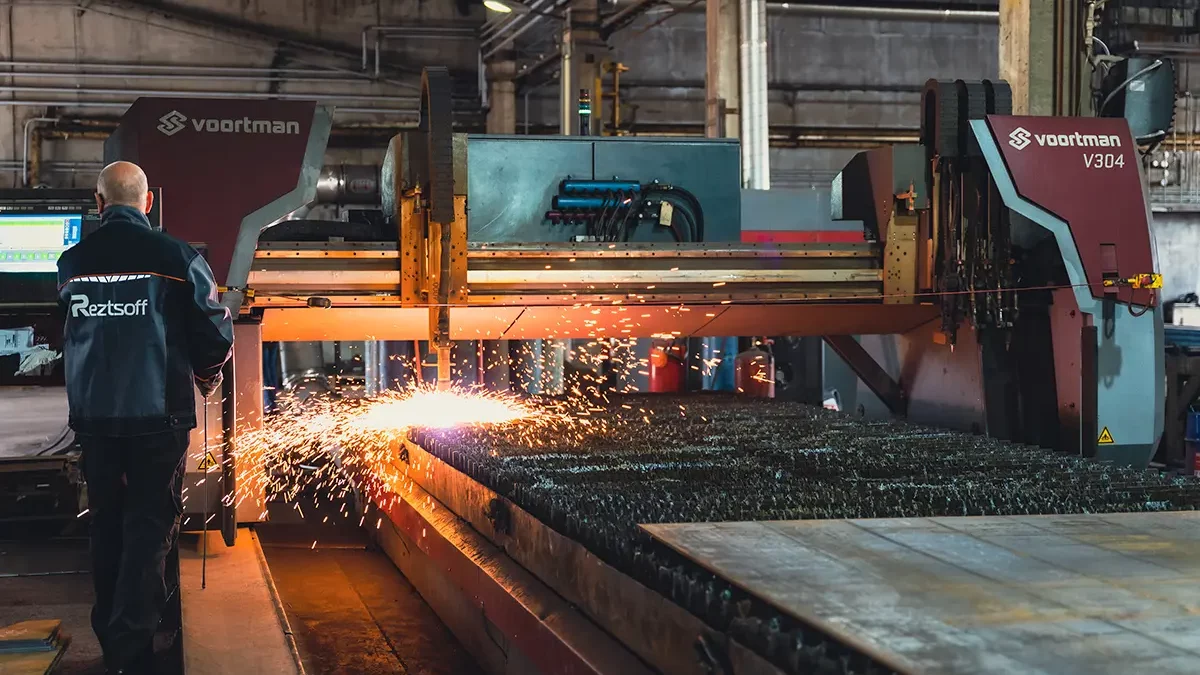

The technical equipment of the metal structure plant is an important parameter that affects the overall performance.

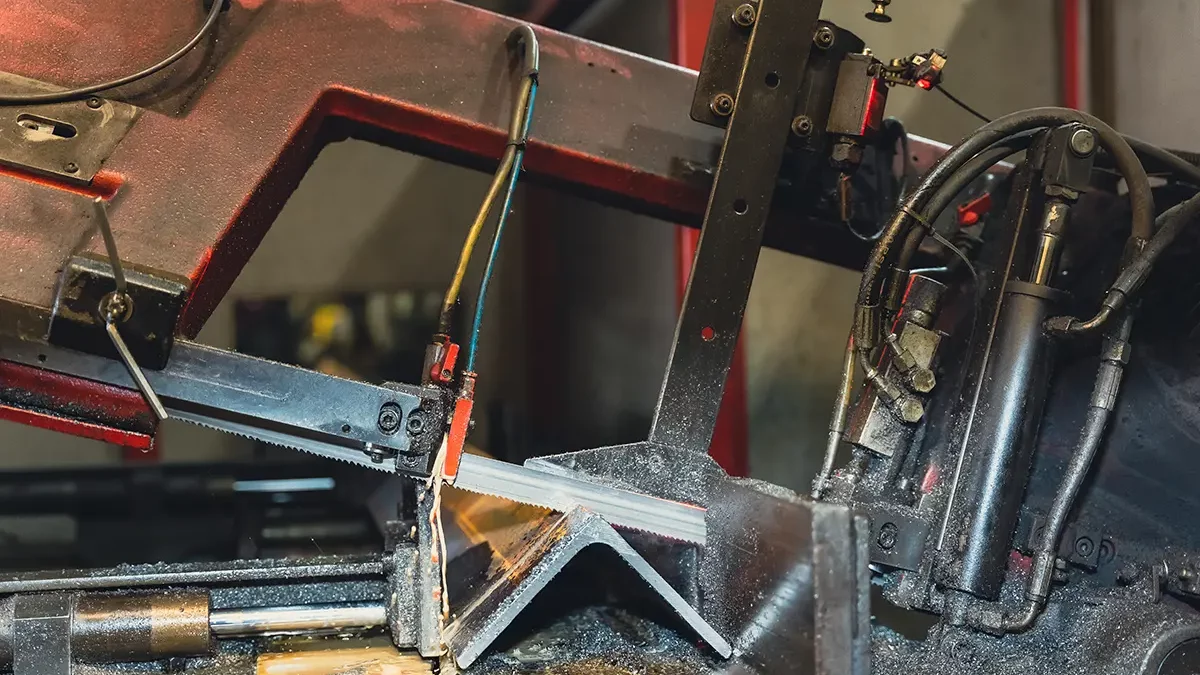

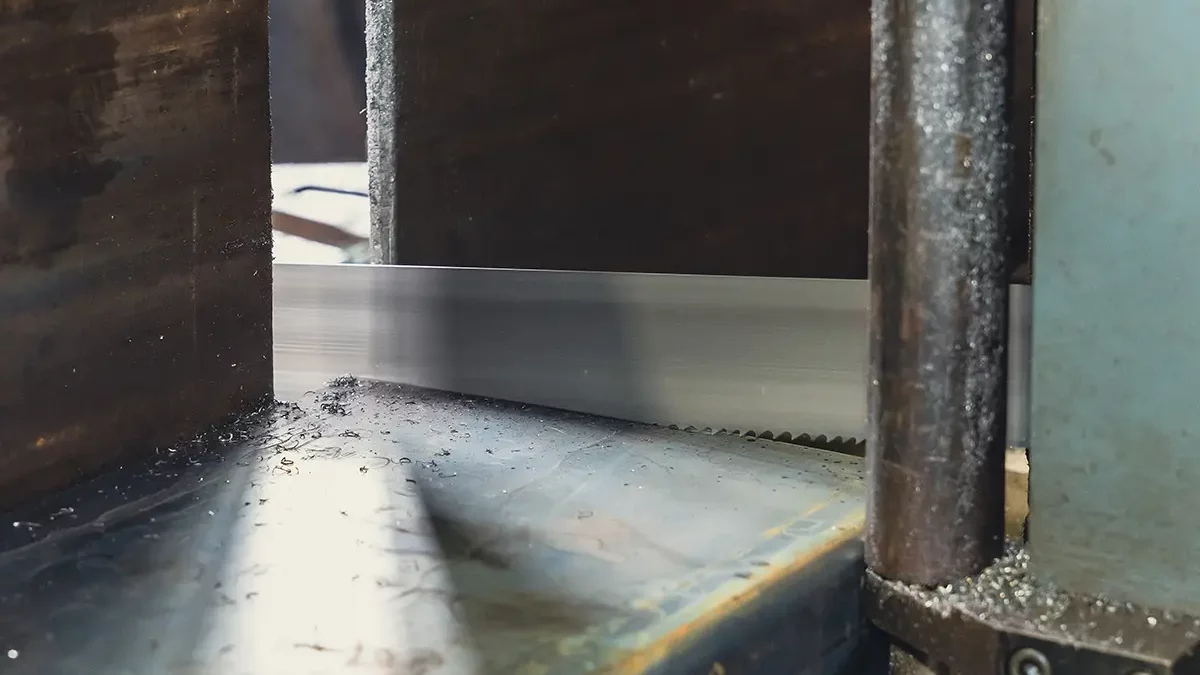

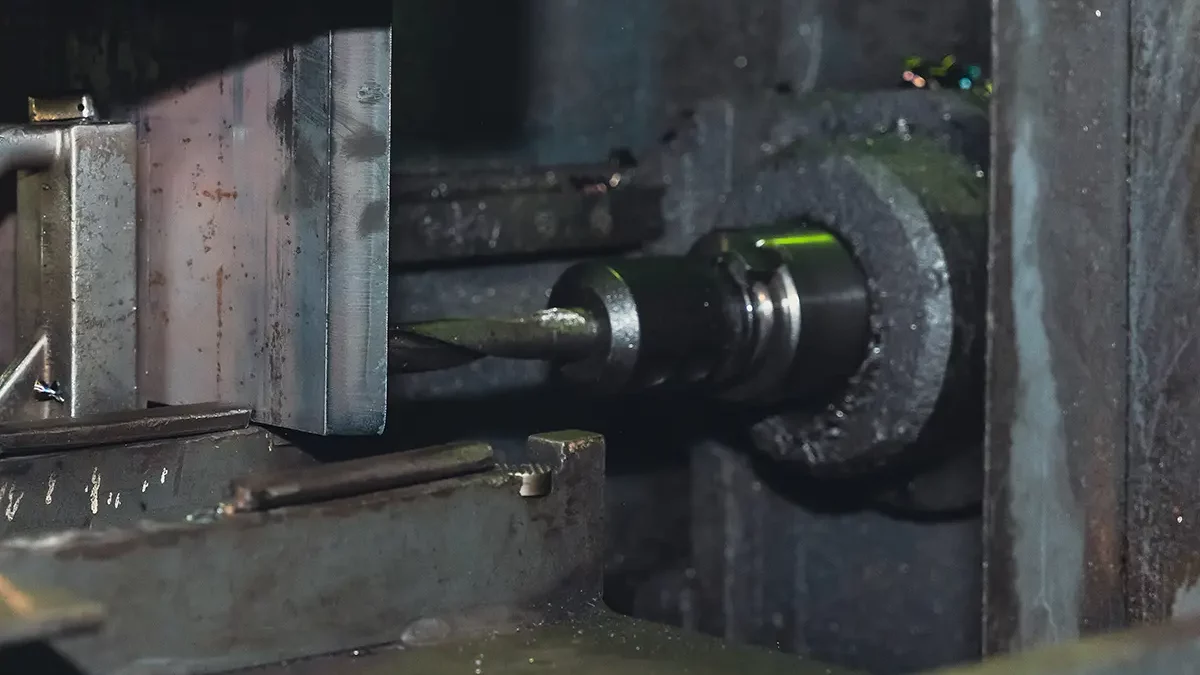

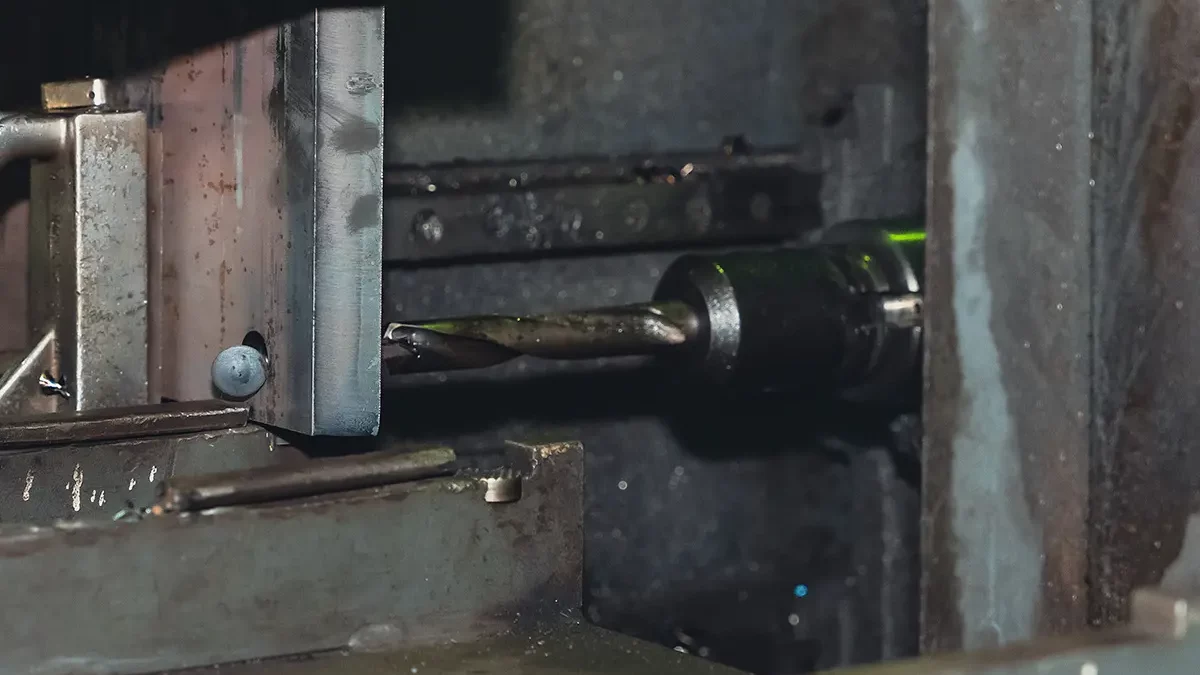

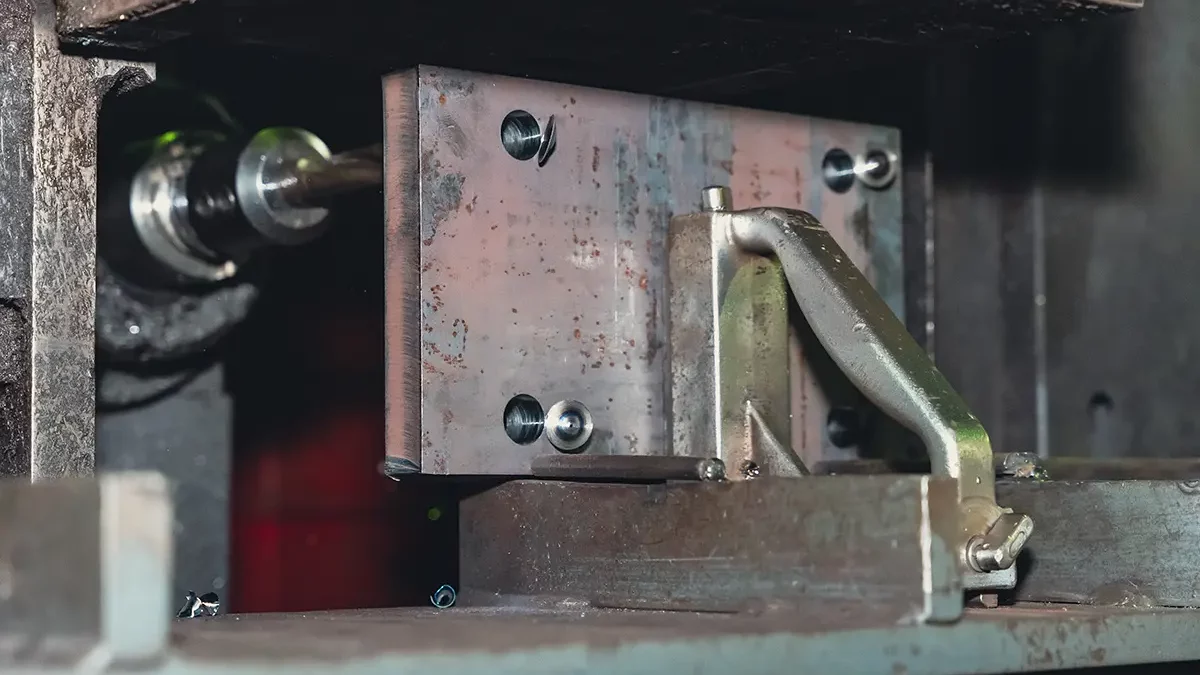

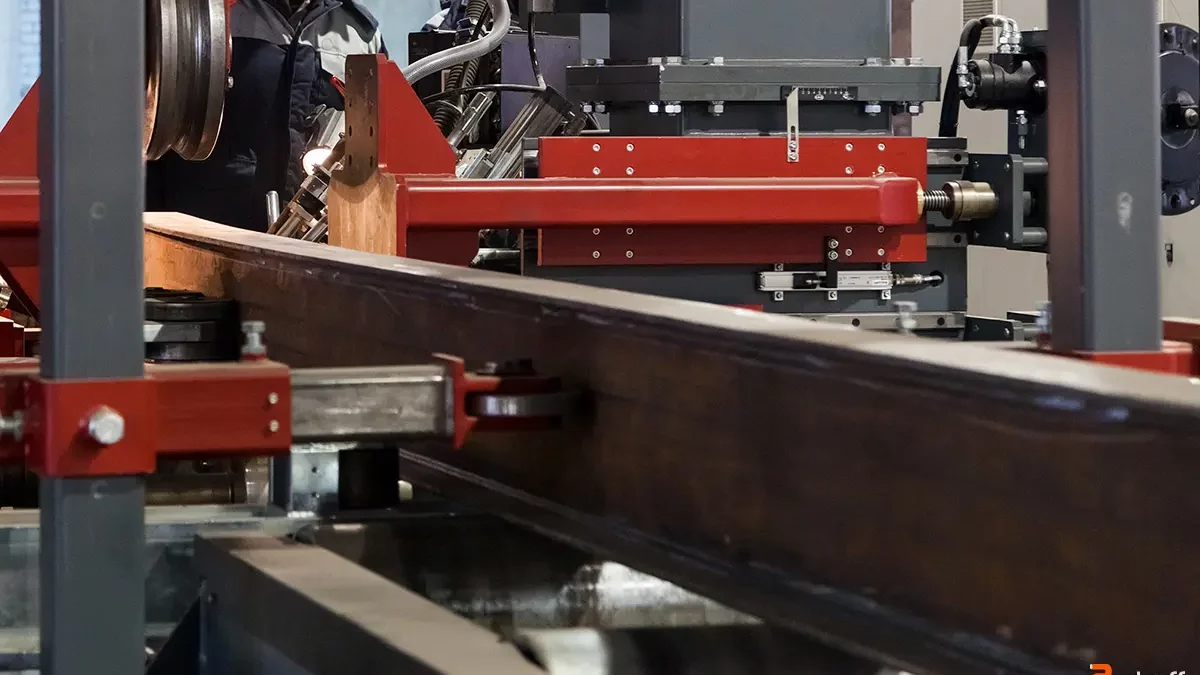

The Reztsoff metal structure plant is equipped with automatic and semi-automatic CNC-controlled lines equipment. Modern lines allow the production of up to 1000 tons of metal structures per month.

We divide the equipment into four areas: