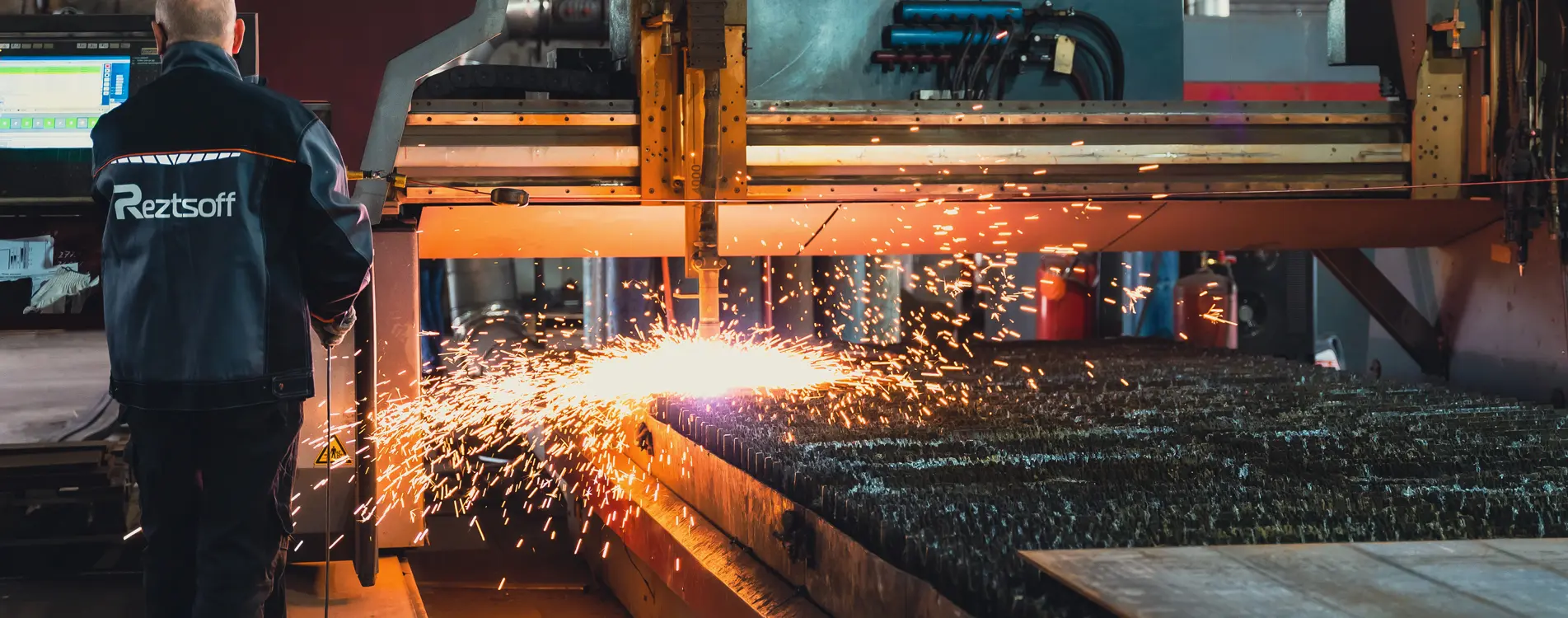

Plasma cutting is one of the most important stages of the blanks. It allows the element design of various configurations: embedded elements, foundation and anchor plates; washers, flanges, jambs, thrust bearings, eyes and other fastening elements, as well as blanks for welded structures.

Thermal cutting machines are located in the blanking shop of the Reztsoff plant.

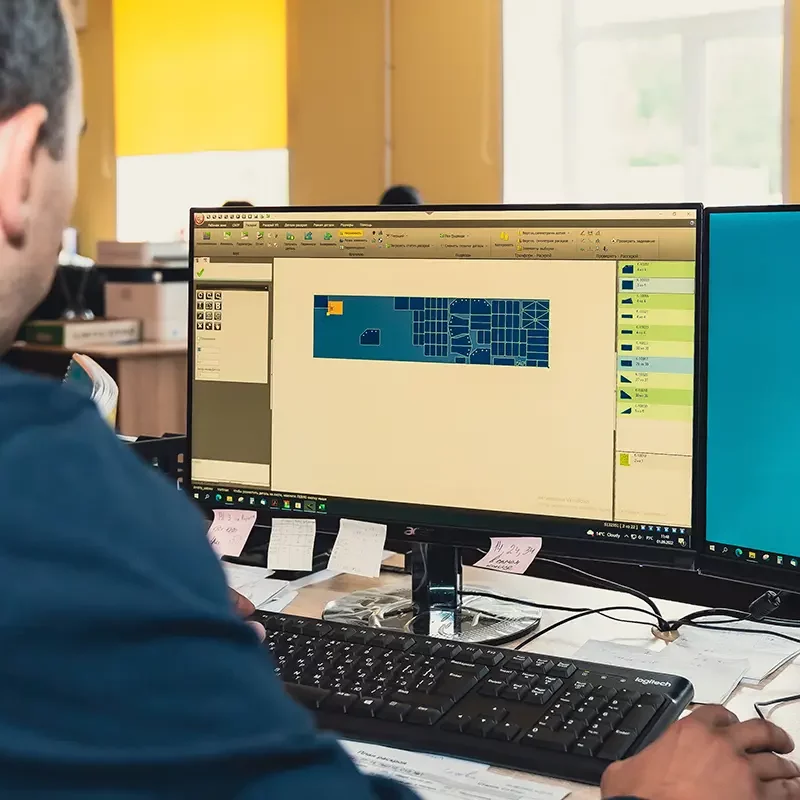

We have two CNC thermal cutting machines: CNCSG300 and VOORTMAN V304, which have tables of 2000×12000 mm and a portal height of 2200 mm, designed for automatic plasma and gas cutting of parts of any complexity from rolled metal.

The thickness of the sheet is from 4 to 100 mm.